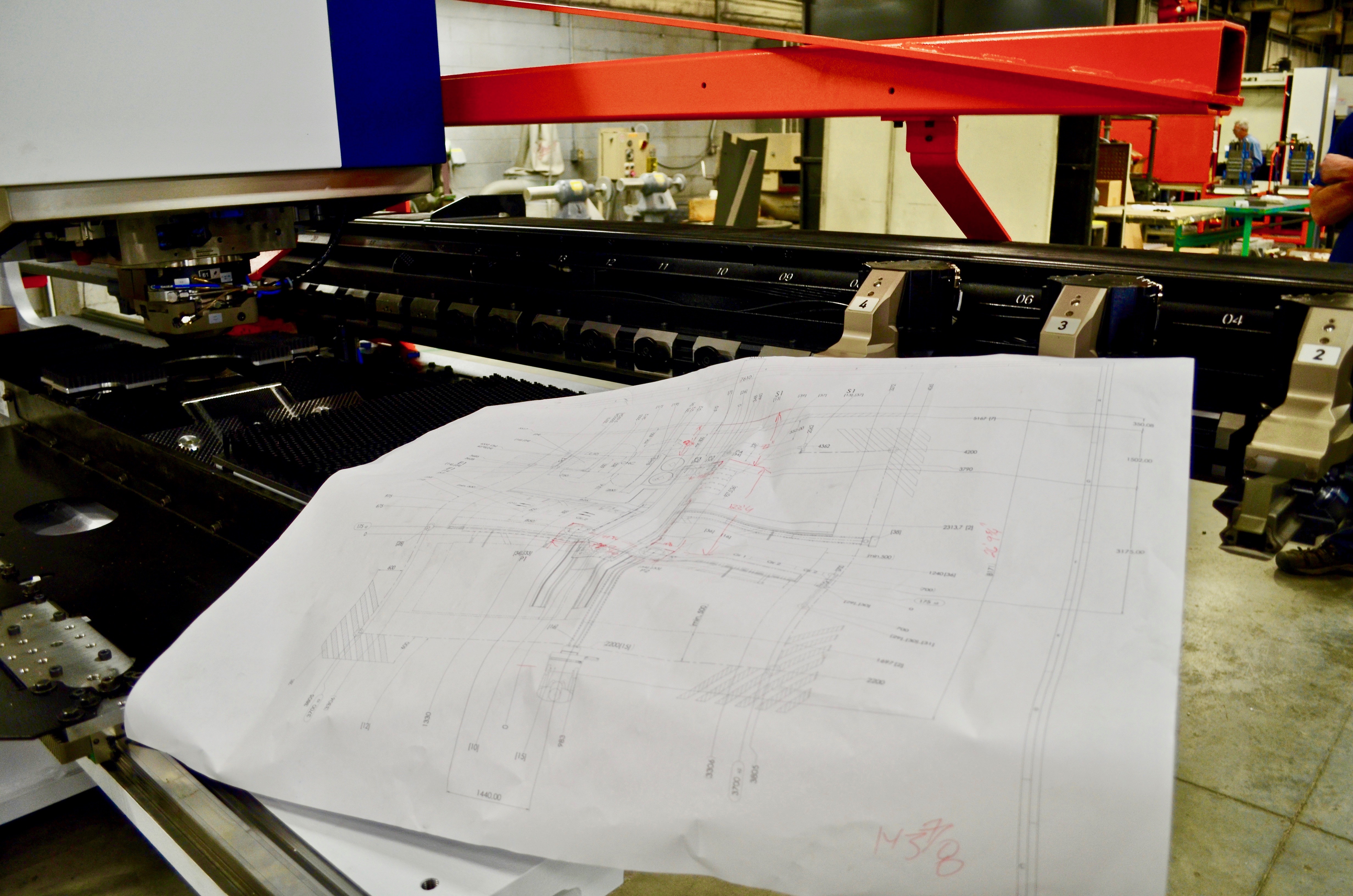

TRUMPF TruPunch 5000

While lasers dominate today’s fabrication world, punching machines still play an important role. In July 2018, Axis upgraded our punching capability by adding a TRUMPF TruPunch 5000, the fastest punching machine in the world. Axis trusts the reliability and quality of TRUMPF machines after many years of using TRUMPF laser cutters. The TruPunch 5000 has many features that we feel make it the best punch made.

Features

The TRUMPF TruPunch 5000 is highly efficient performing at 1350 strokes per minute. Notably, unlike traditional punching machines, the TruPunch 5000 does not have a turret. Tooling is preloaded on a rail where it is mechanically clamped to the hydraulic punching head and die seat when accessed for use. Fastening the punch to the head allows it to be pushed through the work material and then pulled back during the stripping process. This is more dependable than relying on spring pressure to withdraw the punch. Furthermore, the die moves up and down ensuring scratch-free processing, even when forming. The height of the head can be controlled allowing for tapping, forming, and moving the sheet while the head is down. By moving the sheet when the head is down allows etching and use of wheel technology to roll beads and shear edges. It’s 20” x 20” parts chute also permits tab free processing.

A key feature of the TruPunch 5000 is its ability to maintain sheet flatness. By adding curvature to the die, counter-bends can be made, and thereby reversing the induced warping. Retractable clamps ensure the highest quality part and precision along with saving material. Eliminating the need to reposition the sheet while punching greatly improves accuracy between the parts. Furthermore, eliminating the “no punch zone” increases material yield. To better protect both the machine and its user, ball and brush tables reduce noise and provide gentler material handling.

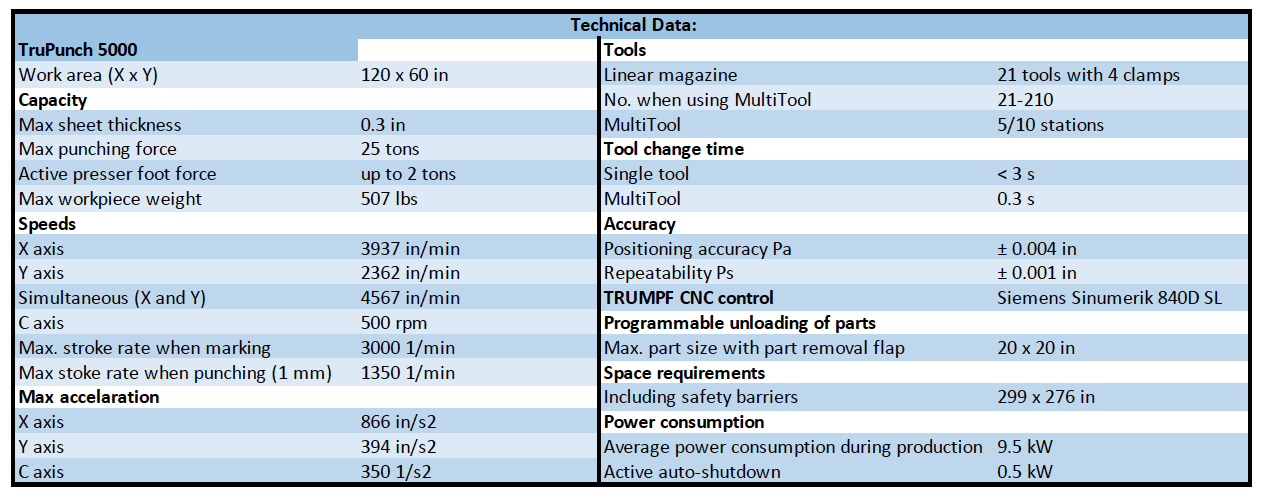

Check out all of the technical data for the TRUMPF TruPunch 5000:

Further reading: Punch Press vs. Laser Cutter